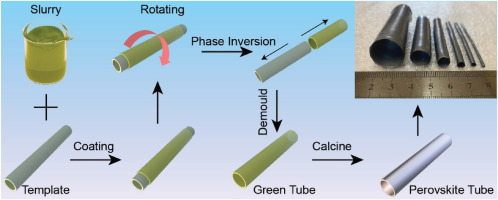

Microtubular/hollow fiber perovskite oxygen transport membranes (OTMs) bring various advantages for oxygen separation from air. The fabrication of tubular membranes is usually obtained by slurry extrusion process through a die system. However, the design and manufacture of the die system is time-consuming and high cost. Once assembled, it lacks flexibility to tune diameter and wall thickness of the resultant tubular membranes, making it difficult to fulfill multifaced requirements for oxygen permeation performance optimization and reliability enhancement. Herein, we report a novel unified approach to fabricate microtubular/hollow fiber ceramic membranes. The approach employs a template-assisted coating process in combination with a rotating strategy, enabling flexible tuning of dimensions and rapid prototyping of ceramic membranes ranging from microtubes to hollow fibers. A family of La0·6Sr0·4Co0·2Fe0·8O3-δ, Ba0·5Sr0·5Co0·8Cu0·2O3-δ, and Sr0·8Ca0·2FeO3-δ microtubular/hollow fiber membranes are fabricated. Both oxygen permeation performances and mechanical properties of the fabricated membranes are systematically measured. Sr0.8Ca0.2FeO3-δ hollow fiber membrane exhibits oxygen separating capability at a record low temperature of 400 °C. Size effects on OTM's permeation performance and mechanical property are investigated, and the trade-off design of tubular OTMs is emphasized towards practical applications.

Click here to go to article